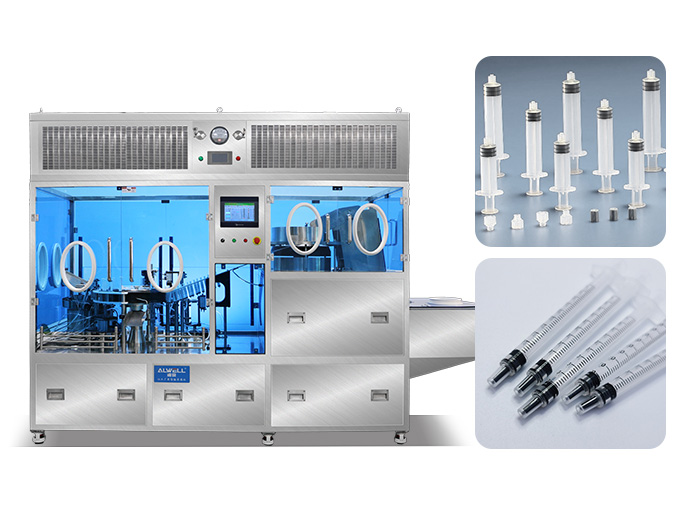

Pre-filled flush syringe filling machine, this equipment is specially designed for plastic syringes and pre-filled needles automatic filling and sealing machine. It can realize automatic pipe, centrifugal pipe management, filling, rotating cap, and can butt lamp inspection, sterilization pendulum, rod, labeling, weight inspection, pillow packaging machine and other automatic assembly line. Machine servo control, stable structure, suitable for a variety of specifications of syringe products, suitable for normal saline, sodium chloride, chitosan, dental gel and other materials filling, widely used in a variety of biopharmaceutical, dental and other industries.

Advantage

1. This product is widely used in various types of pre-filled catheter irrigators, which can realize silicification, filling, rotating cap, lamp inspection, loading and sterilization, rod labeling, packaging finished products and other linkage production lines.

2. Adopt 15" Siemens HD large screen

3. Full Schneider servo system control, accurate filling and capping, filling accuracy ±1%

4. The vacuum gas pipeline is equipped with Burst filter and sanitary diaphragm valve to ensure 100% clean

5. Precise ceramic plug pump, suitable for a variety of materials, high viscosity materials can also be easily filled

6. Automatic feeding system can be selected, using liquid level induction, automatic feeding when there is a shortage of materials.

7. Simple structure design, easy to daily cleaning and maintenance

8. Intelligent software, precise setting of each step.

9. The whole machine SUS304, the parts in contact with the material are made of 316L and medical silicone, which fully meets the requirements of GMP

Parameter

Machine name: prefilled plastic syringe filling machine

Applicable materials: water and paste

Applicable specifications: 1mllong/1-3ml/5ml/10ml/20ml/30ml plastic pre-filled needle syringe (need to replace the specifications)

Filling range: 0.1-30ml(need to replace the plunger pump)

Number of filling needles: multiple

Filling accuracy: ±1%

Production capacity: 2000-4000 PCS/hour

Cap pass rate: ≥99.9%

Equipment noise: ≤70 dB

Total power: about 5KW

Voltage: 380V 50Hz

Compressed air: 0.6-0.7Mpa

Dimensions: 3500*1500*2400(mm) (including laminar flow)

Weight: 800KG

* Note: The above parameters are reference values. Actual parameters vary according to packing materials, filling amount, material characteristics and vacuum degree.